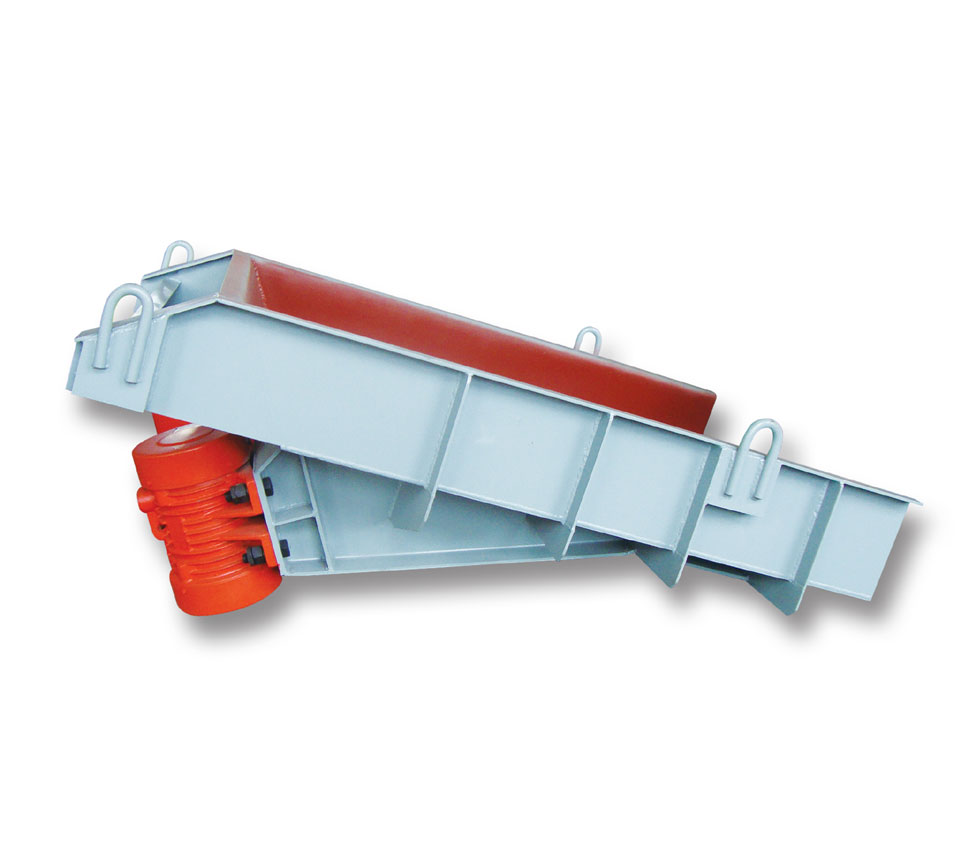

WEIGH FEEDER

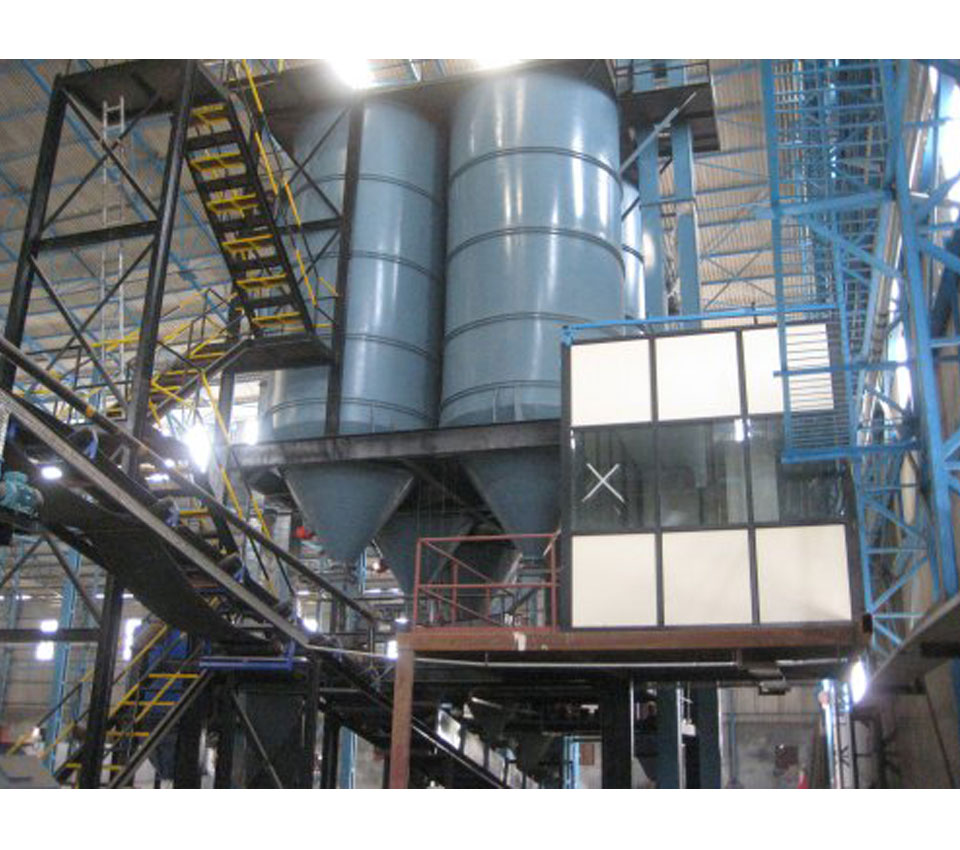

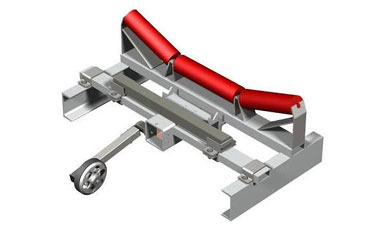

Weigh feeder is a closed-loop control system, which controls the flow of material very accurately using controller and different instruments. This system accepts an external command from process computers like SCADA, HMI, DCS etc. This type of weigh feeder used in industries like Steel Plant, Cement Plant, Fertilizer and Chemical industries.